-

Shanghai Shangshai Bolting cloth Manufacturing Co., Ltd. is a professional mesh manufacturer with two factories. One is located in Xingta Industrial Park, Jinshan District, Shanghai, the other is located in Xutuan Industrial Zone, Anping County, which has the reputation of "Township of Chinese Screen". The company now has more than 300 Sulzer looms, Beninger warping machines, cleaning and setting equipment, laser cutting equipment and ultrasonic welding equipment. The main products are printing and filtering series. Printing products are mainly monofilament printing mesh from 10 to 600 mesh, and common width are 127 cm, 165 cm, 260 cm, 330 cm, the widest can reach 365 cm, special width, specifications and color can be customized. With more than 20 years development and continuous technological innovation, Shangshai launched high-end printing screen mesh series in 2016 for the market, moving towards international high-end technology. The filter products are mainly nylon polyamide, polyester, PP polypropylene, plastic mesh and metal mesh, and can be processed into filter strips, filters, welded tubes, discs, filter cartridges and filter bags , which can be widely used in water filtration, medical filtration, food processing, air filtration, automobile, chemical and other industrial filters. The products are exported to more than 30 countries and regions and widely praised by customers.

-

Production equipment:The company has more than 300 high-end printing and filter machines, such as Sulzer loom with width of 280 cm, 330 cm, 360 cm, 390 cm, Beninger warping machine, washing and setting machine, etc. In recent years, according to the needs of the market and customers, laser cutting machine and ultrasonic welding machine have been introduced into the screen mesh to meet the needs of customers for screen deep processing products.

-

Products and Applications: Specializing in the production of polyester monofilament and multifilament printing screen mesh, nylon filter screen cloth fabric net, filter screen, cutting, welding cylinder, flour milling sifter screen mesh sieve, stainless steel wire mesh, mesh filter bags and other products. Polyester nylon and stainless steel printing screen mesh are mainly used in textile printing, glass-ceramic printing, PCB electronic mobile phone printing and other products. Polyester , nylon, stainless steel filter mesh and deep processing products such as filters, cutting rods, welding cylinders and filter bags are mainly used in water filtration, air filtration, dust coating filtration, powder industry, automobile industry, electronic and electrical industries and industrial filtration.

-

Printing Mesh: 6-420T, 15-420 mesh; color and width can be customized

Filter Mesh: 4-240T; 10-600 mesh; color and width can be customized

Flour milling Mesh Series: GG Series, XX Series, XXX Series, Silk Mesh, MF Series

Stainless steel mesh series: 1-635 meshes, material 304, 316, 316L

Filter bag series: milk filter bag, rosin filter bag, liquid water filter bag, dust filter bag, etc. Can customize wire mesh deep processing products: cutting slices, welded tube, bag filter tube, etc. -

Export countries: the United States, Germany, Japan, Britain, Italy, Russia, Brazil, Turkey, Argentina, Pakistan, Thailand, Singapore, Korea, Mexico and other parts of the world.

-

SS concept: Satisfication leads Success

About us

-

1976

Shanghai shangshai was founded in Anping County, Hebei Province, the hometown of Chinese screen Mesh. It is only a small workshop with two old-fashioned metal screen mesh loom machines. It mainly produces and sells metal screen at that time. Its customers are concentrated in China. -

1997

1997

Shanghai shanghai-Yongheng Screen Mehs Factory was established IN 1997. At the beginning of its establishment, the factory only had only 10 weaving machines. It mainly produced, and sold polyester screen mesh , nylon polyamide screen mesh and metal screen wire mesh for filter and printing. Its products began to be sold abroad. -

2009

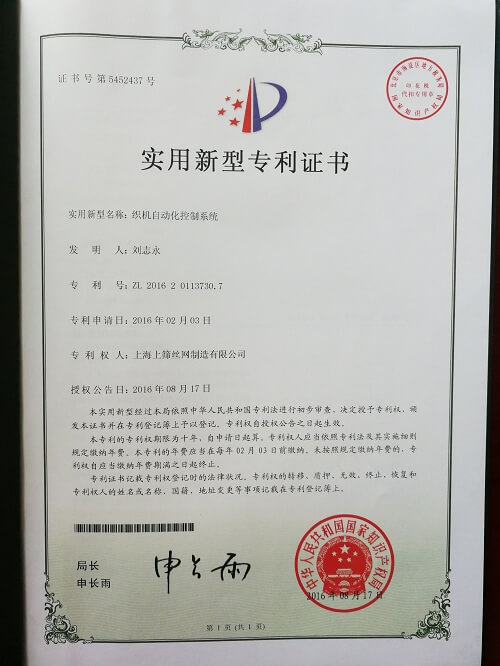

Hebei Shangshai was established in Anping County, and echoes the north and south of Yongheng Screen Mesh Factory in Shanghai. It is equipped with more than 300 Sulzer loom weaving machines and 10 Beninger warping machines. Laser cutting machines, ultrasonic welding machines and filter bag processing machines have been introduced one after another to further meet the needs of customers for further processing products of screen mesh. -

2018

In the year of 2018, The establishment of Shanghai Shangshai Jinshan Factory further enlarges the company's scale, meets the needs of customers for the quantity and quality of screen products, and provides one-stop screen solutions for domestic and foreign customers. -

Now

Now

Shangshai has more than 350 sets of equipment, 260 employees and among them more than 20 are mid-term and senior technicians. It has formulated a set of strict process specifications from raw materials to finished products. The quality of products has been continuously improved. Some products have replaced international high-end brands and are widely used in high-tech industries. The products are exported to more than 30 countries and regions, and have been widely praised by customers.

-

Factory in Anping

-

Workshop for Weaving

-

Workshop for Heat setting

-

Finsihed Goods Workshop

-

Finished Goods Packing

-

Finished goods packing

-

Metal screen mesh inspection

-

Strength Test

-

Ccustomer Inspection

-

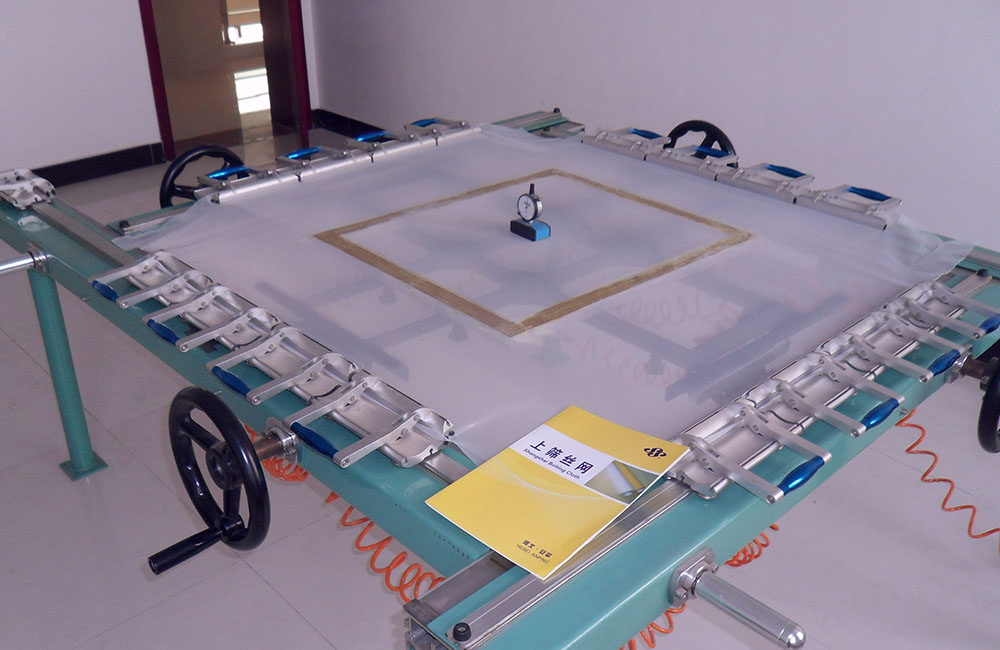

Applicant is making frame

-

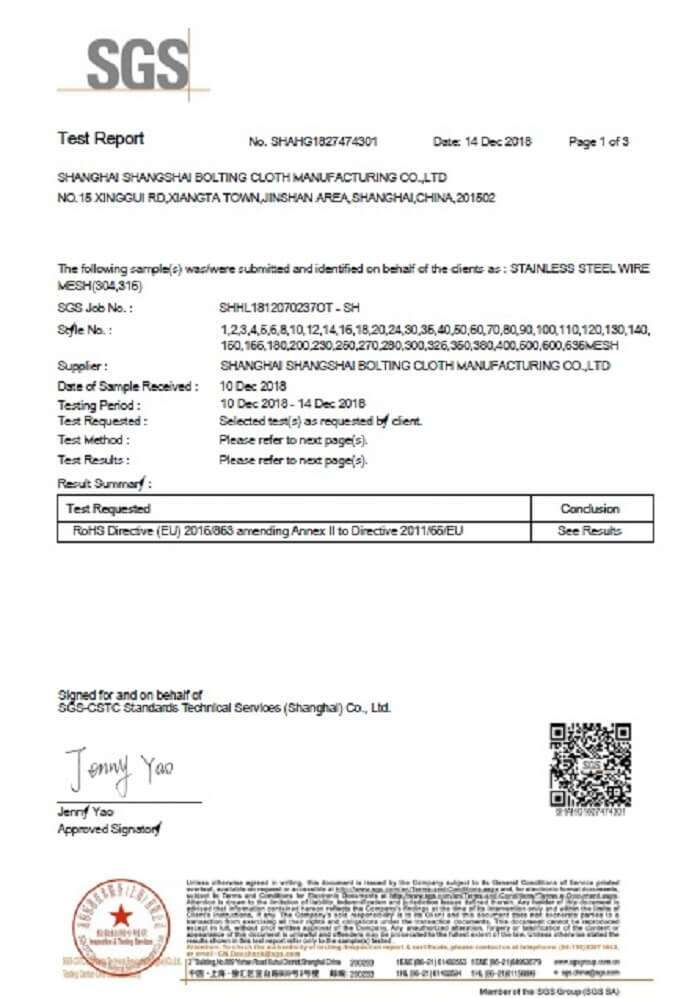

SGS Inspection

-

Loading to container

-

PP-SGS

-

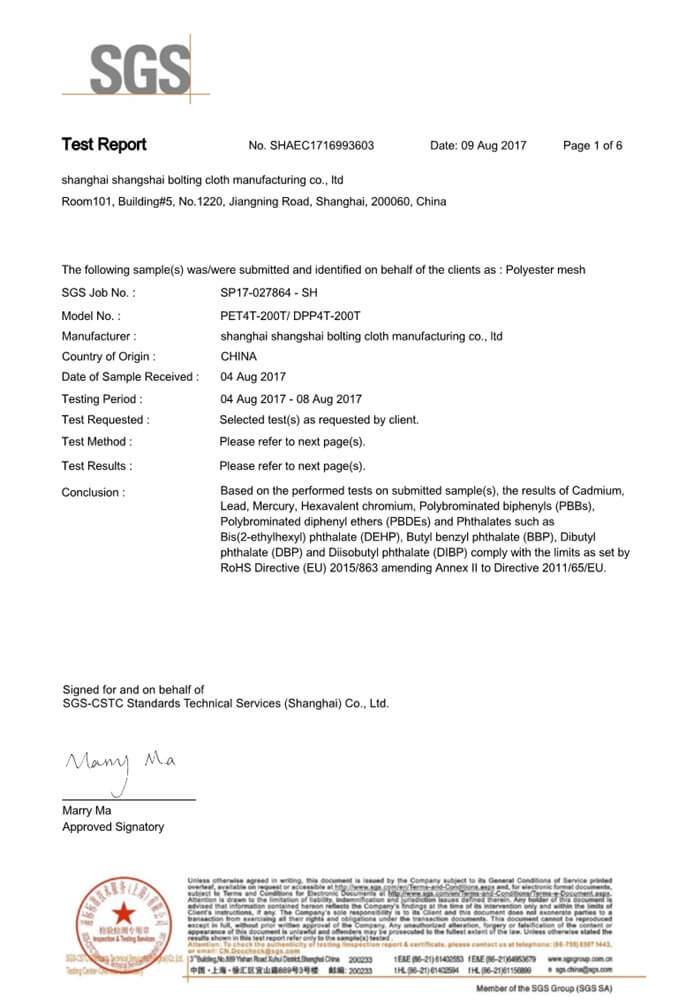

polyester-FDA

-

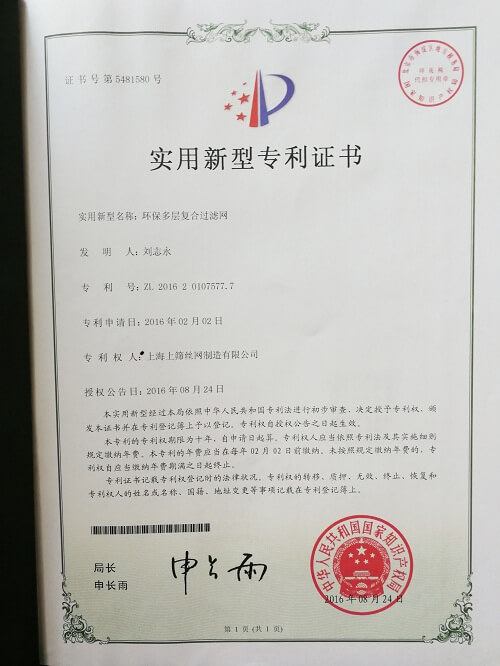

polyester-Rohs

-

nylon-FDA

-

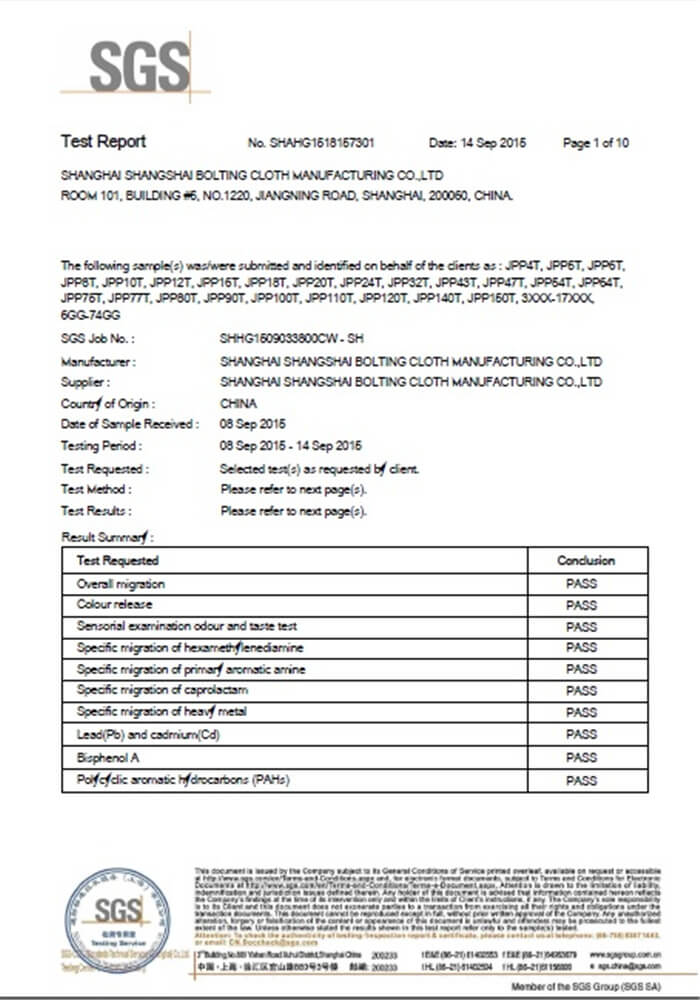

nylon-LFGB

-

nylon-Rohs

-

stainless steel-Rohs

-

PP-Rohs

-

-

-

-